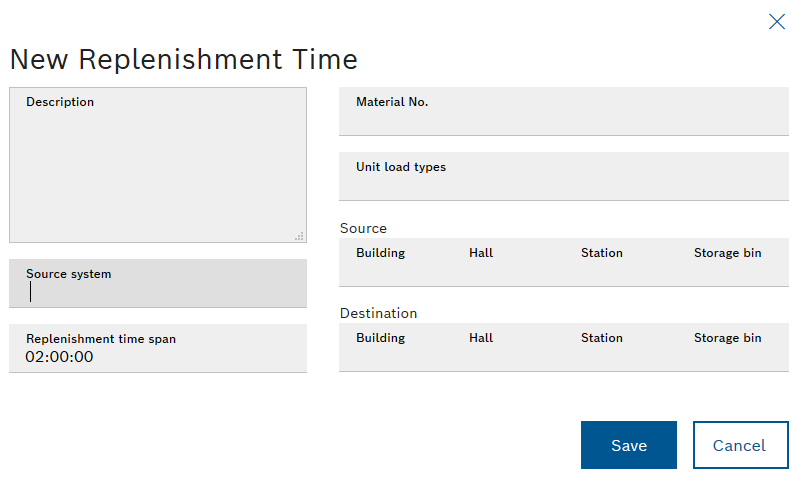

The fields Source system, Material number, Load unit type, Start and Target can be used as filters. If a transport order meets the filter criteria, the Replenishment lead time for this transport order is automatically entered. If no filter criteria are defined, the input Replenishment lead time applies to all transport orders.

Select the hall, station and storage location where the replenishment lead time is to start from the drop-down lists.

Select the hall, station and storage location where the replenishment lead time is to end from the drop-down lists.

Example of a defined replenishment lead time: For all materials that come from hall 1, station warehouse 1, storage location 1 and are to be delivered to hall 2, station warehouse 2, storage location 2, a replenishment lead time of 5 hours should apply. In this example, the filter criteria are Source and Target.

- Enter the description in the Description field, e.g.: Materials from hall 1, storage location 1 to hall 2, storage location 2.

- Enter five hours in the replenishment lead time field.

- In the Source field, select hall 1, station warehouse 1 and storage location 1 from the drop-down lists.

- In the Target field, select hall 2, station warehouse 2 and storage location 2 from the drop-down lists.

The replenishment lead time of 5 hours applies to all transport orders that fulfill the filter criteria (start, target).