Under Planning & control > Orders, order details and the station counter can be viewed and edited in the Orders tab, which is accessed via the Options menu ![]() .

.

Order, Details 1 Tab

Element |

Description |

|---|---|

Part count |

Enter the number of parts to be produced. |

Type Number |

Enter the part type number. |

Type Variant |

Enter the type designation. |

Cycle time |

Enter the time, in seconds, that is needed to complete a part of the order. |

Priority |

Enter the order priority. Values: 0 … 1000, default value: 500 The priority can only be entered when the order is created. The order priority does not affect the sequence in which the orders are processed in the Nexeed Order Management module. |

Part Type |

Select the part type (serial, repair, retrofit etc.). |

Setup |

Enter the name of the setup required for production. |

Customer |

Enter the customer name. |

Description |

Enter production or planning-related comments (maximum of 80 characters). |

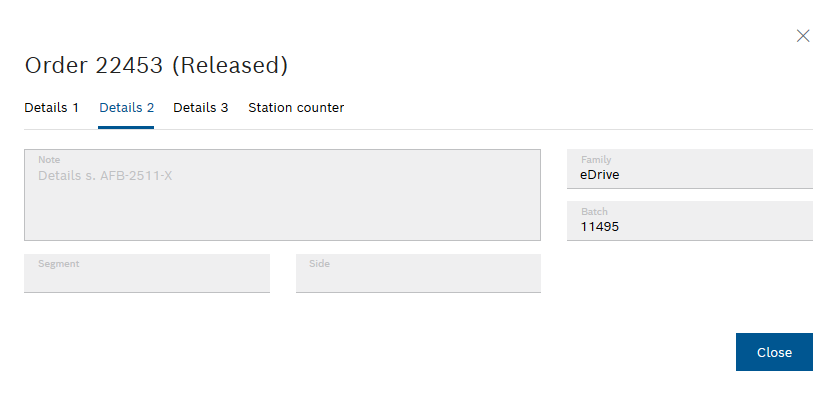

Order, Details 2 Tab

Element |

Description |

|---|---|

Note |

Enter a comment about the order (maximum of 399 characters). |

Family |

Product type family This is entered via the ERP Connectivity interface. |

Batch |

Batch designation This is entered via the ERP Connectivity interface. |

Segment |

For insertion machine lines only: Enter segment (top or bottom segment). |

Side |

For insertion machine lines only: Enter the side of the printed circuit board to be tooled (bottom or top). |

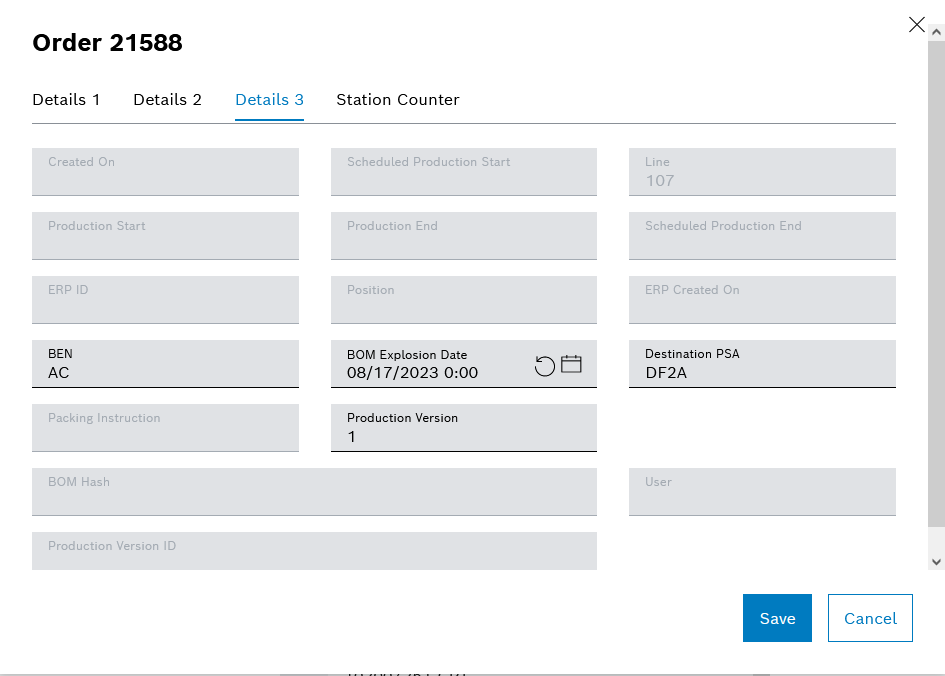

Order, Details 3 Tab

Element |

Description |

|---|---|

Created on |

Date of order creation |

Scheduled production start |

Planned production start date |

Line: |

Line name |

Production start |

Date of actual production start |

End of production |

Date of actual production end |

Scheduled production end |

Planned production end date |

ERP ID |

ERP order ID This is entered via the ERP system. |

Position |

Reference to the order position in the ERP collective order This is entered via the ERP system. |

ERP created on |

Date on which the order was created in ERP |

BEN |

BOM explosion number Enter the revision number for the bill of materials. (Only for orders in the Planned status.) |

Date of BOM explosion |

Enter the date and time of the bill of materials revision. Use |

Target PSA |

Enter the production supply area at which the end product of production from this order is to be used again. |

Packaging instruction |

Requirements for the packaging of the parts |

Production version |

Enter a production version, so that the BOM can be queried by the PSM. (Only for orders in the Planned status.) |

BOM Hash |

Bill of materials designation This is entered via the PSM (Product Setup Management) service. |

User |

Order Management user |

Production version ID |

Production version identification number This is entered via the PSM service. |

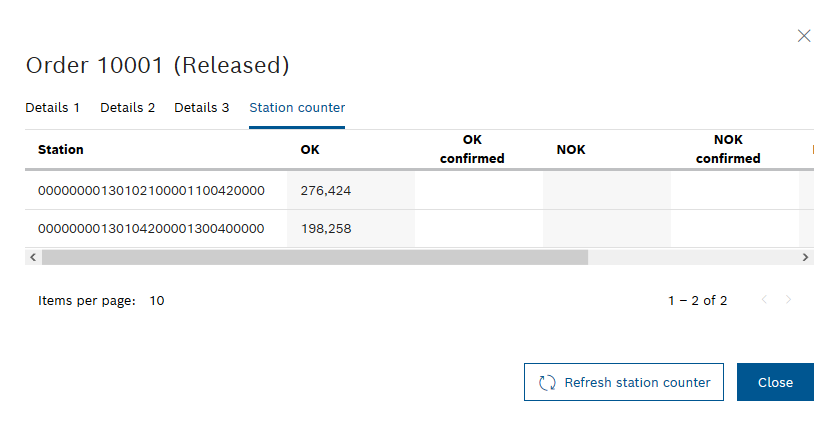

Order, Station Counter Tab

The columns can be sorted in ascending or descending order by clicking on an entry in the header.

Element |

Description |

|---|---|

Station |

Name of station |

IO |

Number of good parts reported by the station |

OK confirmed |

Number of good parts reported to the ERP system |

NOK |

Number of bad parts reported by the station |

NOK confirmed |

Number of bad parts reported to the ERP system |

Repair |

Number of repaired bad parts reported by the station |

Repair confirmed |

Number of repaired bad parts reported to the ERP system |