The Nexeed Order Management module can calculate and provide the material demand needed for the production of an order (SrS). A connection to the Nexeed Material Management, Nexeed Product Setup Management and Nexeed ERP Connectivity modules is required.

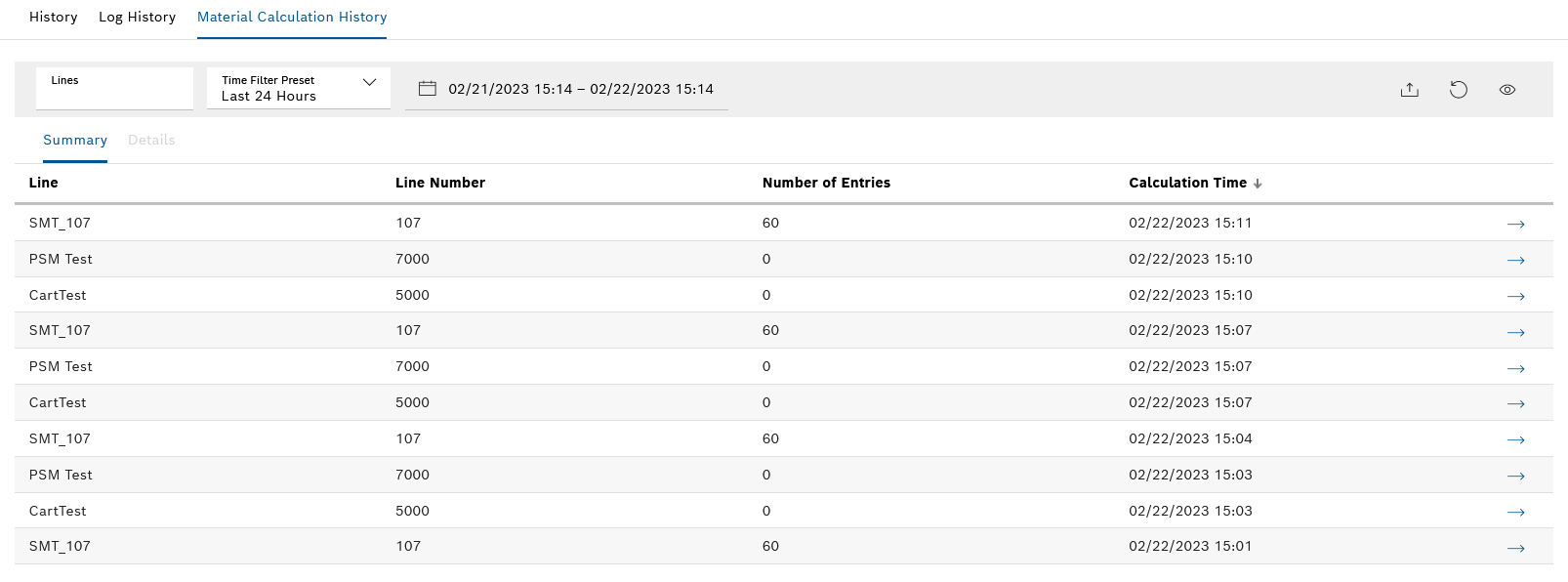

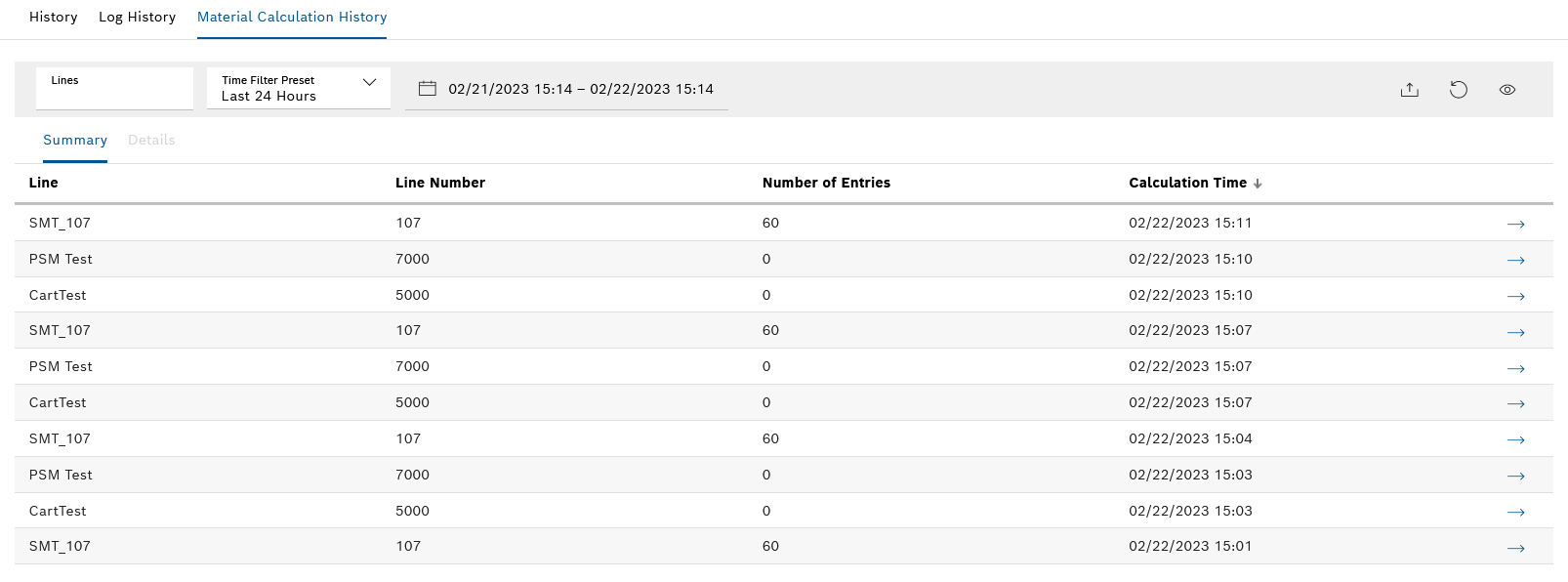

Under Planning & control > History, the Material calculation history tab displays the material calculation history for the order on the line.

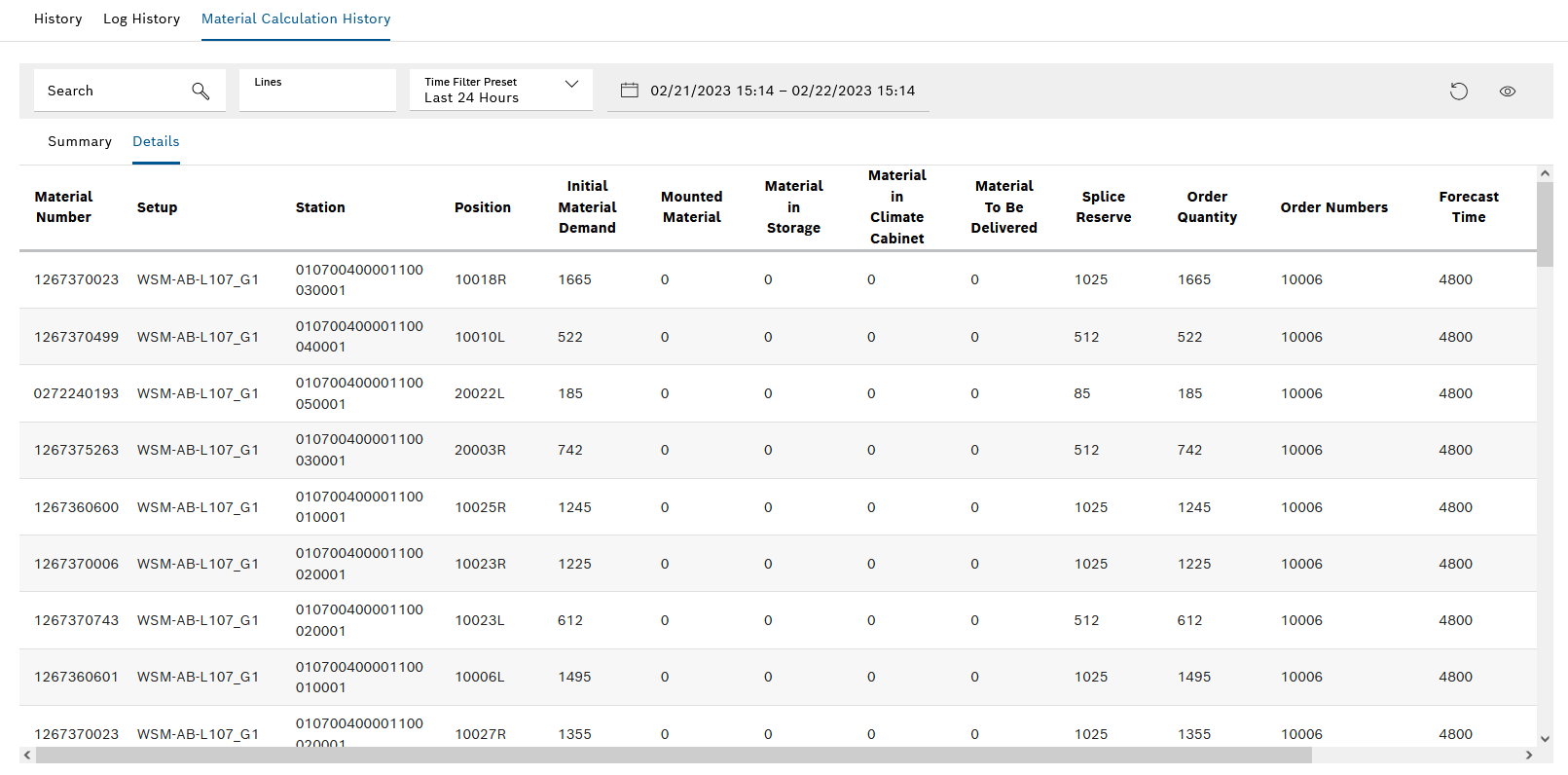

The display is divided into two tabs:

Information on material calculations for all lines.

Detailed information on a selected material calculation for a line.

Overview tab: Header

Element/icon |

Description |

|---|---|

Line(s) |

Filter by lines. Enable the required lines in the list box. |

Time filter preset |

Preset the time range for which the log history is to be displayed. |

|

Enter the start and end dates and time to obtain the exact time range. |

|

Filter the display by order numbers, key figures, setups, stations, type numbers and type variants. |

|

Export the history as a CSV file (e.g., an Excel table). |

|

Reset all filters. |

|

Select table columns to display. |

Overview tab: Table columns

Element |

Description |

|---|---|

line |

Line name |

Line number |

Number of the line |

Number of entries |

Number of entries |

Calculation time |

Time at which the material demand was calculated |

|

Call up details on the material calculation. |

Details tab: Header

Element/icon |

Description |

|---|---|

|

Filter by material number. Enter the material number in full or in part. |

Line |

Select the lines for which the material calculation history is to be displayed. |

Time filter preset |

Preset the time range for which the material calculation history is to be displayed. |

|

Enter the start and end dates and time to obtain the exact time range. |

|

Export material calculation history as a CSV file (e.g. Excel table). |

|

Reset all filters. |

|

Select table columns to display. |

Details tab: Table columns

Element |

Description |

|---|---|

Material number |

Number of the material |

Installation |

Setup that must be installed for the material |

Station |

Station where the material is required |

Position |

Position of the station where the material is required |

Initial material demand |

Amount of the material that must be provided for production |

Installed material |

Quantity of the material that is on the line |

Material in the depot |

Quantity of the material that is in the warehouse |

Material in the climatic chamber |

Quantity of the material that is in the climatic chamber. |

Material to be delivered |

Quantity of the material required for the order |

Splice reserve |

Minimum amount of material that must be set up in order to splice on new material and thus avoid an interruption in production. |

Order quantity |

Quantity of the material reserved for the order |

Order number |

Number of the order |

Forecast time |

Expected production time of the order |

Material to be ordered |

|

Exclusion list |

Material type numbers of materials that are not included in the material calculation

|