The line for which the splice prediction is to be displayed can be selected.

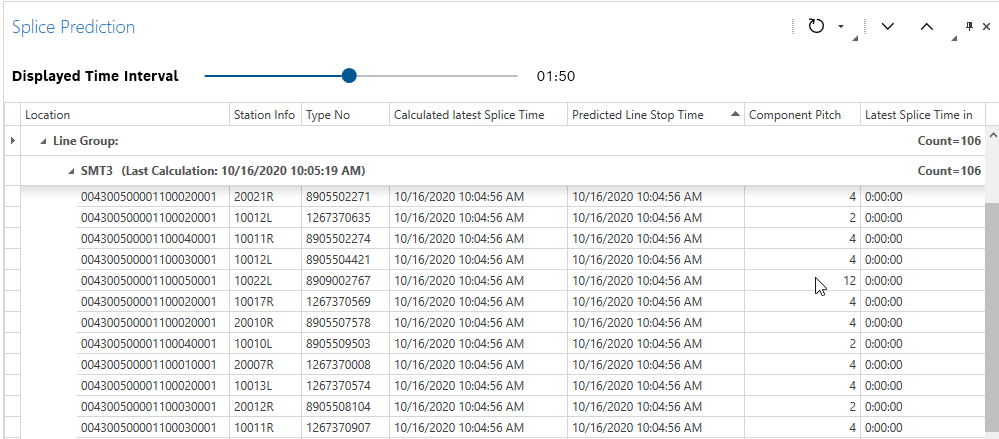

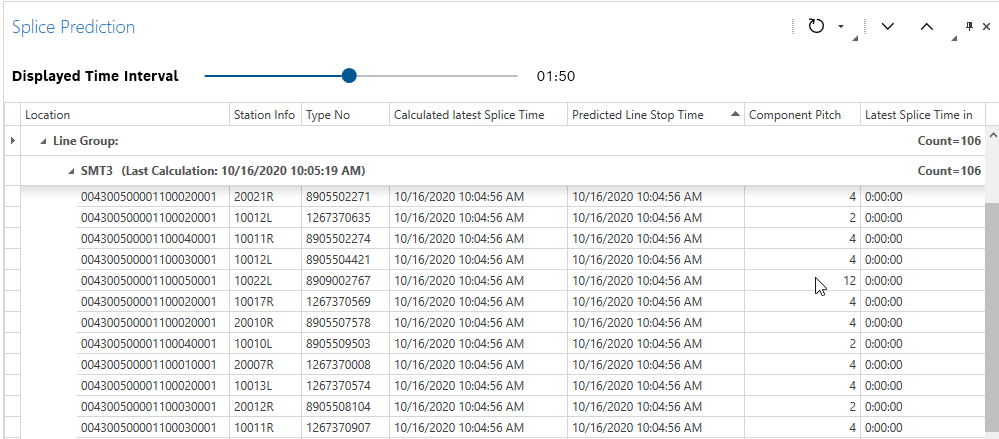

The splice prediction data for the selected line is displayed in a tree structure sorted by line group.

Splicing is the joining of two materials, usually in the form of rolls, tapes or cords.

Materials can only be spliced if one or both materials have a minimum length. The total length of the material after splicing must be taken into account during the production process.

The Splice Prediction menu has two windows:

Overview of the user interface

Specific icons and elements in the Splice Prediction window:

Icon/element |

Description |

|---|---|

|

Open the line grouping in the tree structure. |

|

Close the line grouping in the tree structure. |

|

Slider for the Displayed Time Interval Filters the Calculated latest Splice Time column on the basis of the last calculation. Only splice prediction data for the selected time interval is displayed. |

Location |

Location where the material is spliced |

Line |

Track of the line to be spliced |

Material No. |

Material number of the material being spliced |

Calculated latest Splice Time |

Difference between the last possible splice time and the last calculation time. If the time has elapsed, it may not be possible to successfully splice the material because the material length is inadequate. |

Predicted Line Stop Time |

The time when the production line must be interrupted due to a lack of material |

Component Pitch |

Distance between two materials being spliced in millimeters The gap is relevant if the materials available for the production line, e.g. EPROMs, exist in the form of rolls. |

Latest Splice Time in |

Displays the time remaining until the next splicing operation. |

line |

The line selected in the Lines window for which the splice prediction data is displayed |

Line Group |

Name of the group to which a line belongs Production lines are grouped according to specific production criteria. |