Lines including their locations (stations, handovers and storage cabinets) are created and configured in the Admin Settings menu. You can also define configuration rules that apply to materials.

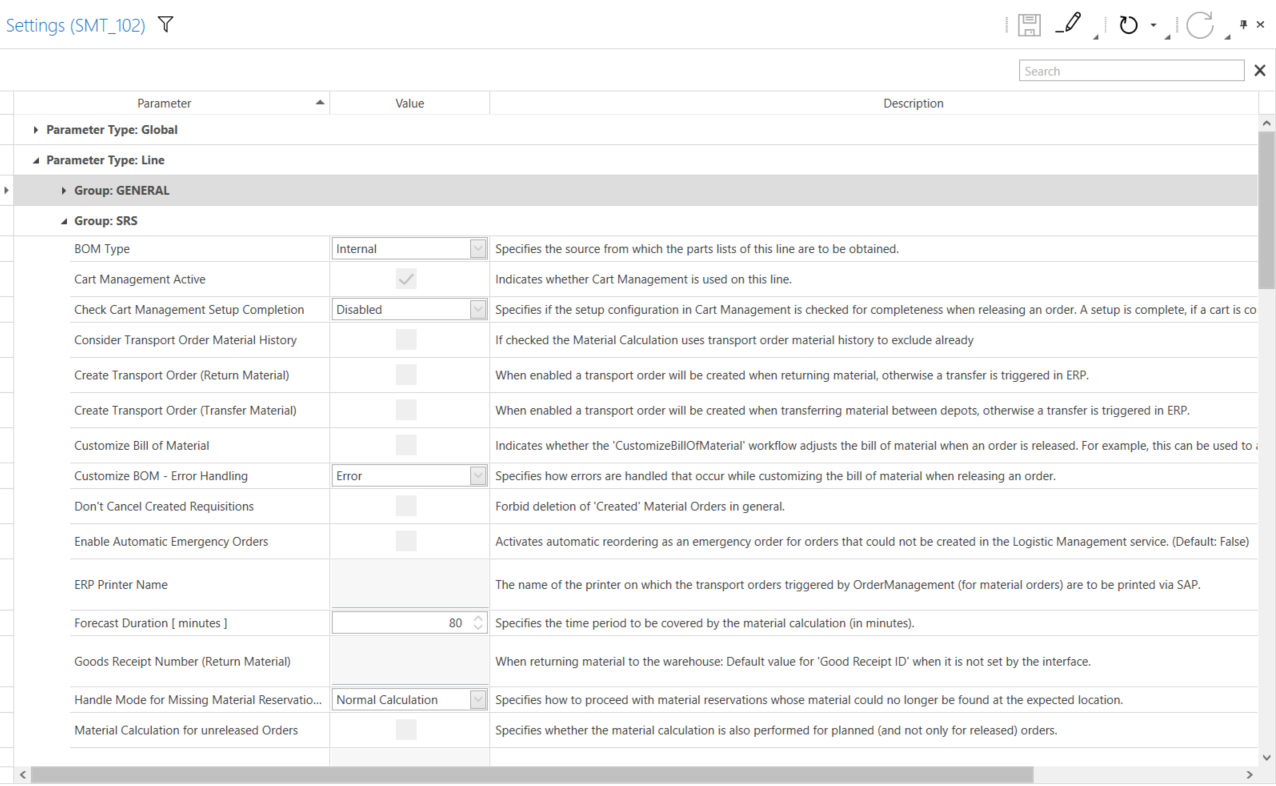

The parameters for production lines are edited in the Settings window in the, Admin Settings menu. The lines with parameters to be edited are selected in the Lines window. It is possible to execute a change operation for multiple lines at once by using the multiple selection keys [CTRL and/or SHIFT].

The settings are divided into three areas:

General settings (e.g. to generate part identifiers), SRS settings

General settings (e.g. status changes of an order), SRS settings

General settings, settings for the station

Use ![]() to reset the settings.

to reset the settings.

Table Columns

Column |

Description |

Parameter |

Name of the parameter |

Value |

Parameter value |

Description |

Description of the parameter |

Global parameter |

Check the checkbox to apply the parameter to all lines. |

Changed |

Indicates that the parameter has been changed |

Tags |

Classification of parameters The following tags can be used: Material orders, bill of material, SRS, reservation, request, spare parts, cart management, order synchronization, order confirmation, material calculation. |

General settings

Parameter |

Description |

|---|---|

Order Synchronization Mode - Subscription |

Specifies how to subscribe for notifications about updates of orders. This setting is also used to determine which type of orders can be downloaded using a service interface / workflow (Activity: DownloadOrder) without specifying the line. Deactivated: No subscription is made and no orders can be downloaded using a service interface / workflow. ERP Production: A subscription is created to receive notifications for Contract Production Orders (ERP: Production Orders) from ERP. Contract Production Orders can also be downloaded through a service interface / workflow. ERP Production Planned (Current Line): Series Production Orders (ERP: Production Planned Orders) can be downloaded through a service interface / workflow. ERP Sales: A subscription is created to receive notifications for Sales Orders from ERP. |

Use Unique Part Identifiers |

Default value in case the line parameter Use Unique Part Identifiers' is needed but the request could not be associated with a line. Find more information in the description of the line parameter. |

Unique Part Identifier Creation (Scrap Parts) |

Default value in case the line parameter 'Unique Part Identifier Creation (Scrap Parts)' is needed but the request could not be associated with a line. Find more information in the description of the line parameter. |

Material Order Mode |

Specifies whether material should be ordered manually via 'Trigger material order' or automatically. |

Unique Part Identifier Creation |

Source for the creation of part identifier

|

Save Reported Components |

Enable or disable globally whether components are saved for feedback |

ERP Default Plant |

Default value for the plant in requests sent to the ERP system. |

Maintenance Mode |

If active and the parameter 'No Material Order in Maintenance' is set in the global parameters, no material requisition is triggered. The station counter is not increased. Maintenance mode can also be enabled and disabled in the order view for scheduled orders if the client is configured to allow this. |

SrS settings

Parameter |

Description |

|---|---|

SRS active |

Enables or disables the SRS which performs the material calculation among other things. |

Calculation interval [seconds] |

Interval at which the material calculation is to be performed |

Use material reservation |

Select or deselect whether or not the reserved material is taken into account in the material calculation or if material should be reserved. |

Material delivery mode |

Specifies whether an additional status (delivered) is to be used as the final status for material orders: Single-Stage: Completed is used as the final status. The state of a material requisition is changed to completed when the material is removed from the warehouse. Two-Stage: Delivered is used. The state of a material requisition is changed to in delivery when the material is removed from the warehouse. When the material is delivered to the line (handover) the state of the requisiton is changed to delivered. |

Forecast Duration [minutes] |

Time in minutes to be covered by the material calculation |

Basis for required handover material |

Determines which orders are considered when calculating the required material for a handover location. |

Rest Strap length [mm] |

Minimum belt length required to splice material (in mm). Relevant for the calculation of how much material is required and when. |

No Material Order in Maintenance |

If enabled, no material is ordered for lines in maintenance mode. |

Automatically Close Requisitions (Cancellation Requested) |

Time span ([d.]hh:mm:ss) to automatically close material requisitions in the state 'Cancellation requested' with state reason 'Timeout'. e.g. 1.12:00:00 (one day and 12 hours) This is the maximum time the asynchronous response from the erp system to cancel the requisition may take. To disable the automatic closing of material requisitions for this state, the field can be left empty. |

Automatically Close Requisitions (Requested) |

Time span ([d.]hh:mm:ss) to automatically close material requisitions in the state 'Requested' with state reason 'Timeout'. e.g. 1.12:00:00 (one day and 12 hours) This is the maximum time the asynchronous response from the erp system may take. To disable the automatic closing of material requisitions for this state, the field can be left empty.. |

Automatically Close Requisitions (Created) |

Time span ([d.]hh:mm:ss) to automatically close material requisitions in the state 'Created' with state reason 'Timeout'. e.g. 1.12:00:00 (one day and 12 hours) This is the time it may take until the material is scanned in the warehouse and is in delivery. To disable the automatic closing of material requisitions for this state, the field can be left empty. |

Automatically Close Requisitions (In delivery) |

Time span ([d.]hh:mm:ss) to automatically close material requisitions in the state 'In delivery' with state reason 'Timeout'. e.g. 12:00:00 (12 hours) Only relevant if finally delivered is active. The time between scanning the material in the warehouse and it being delivered may not exceed this time. To disable the automatic closing of material requisitions for this state, the field can be left empty. |